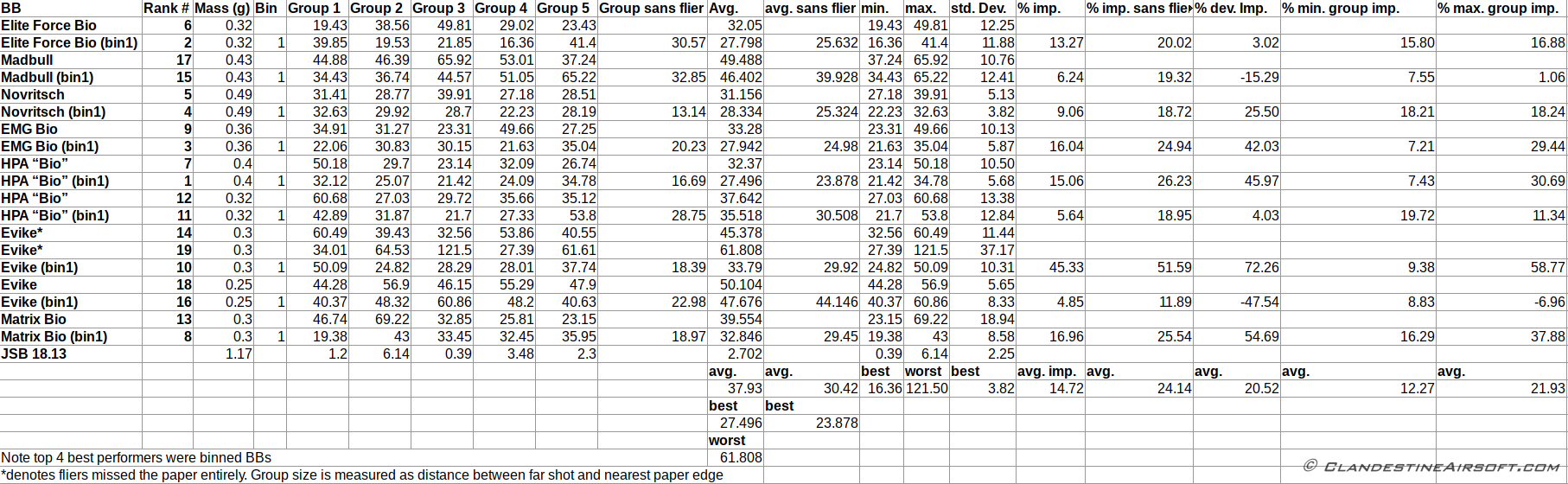

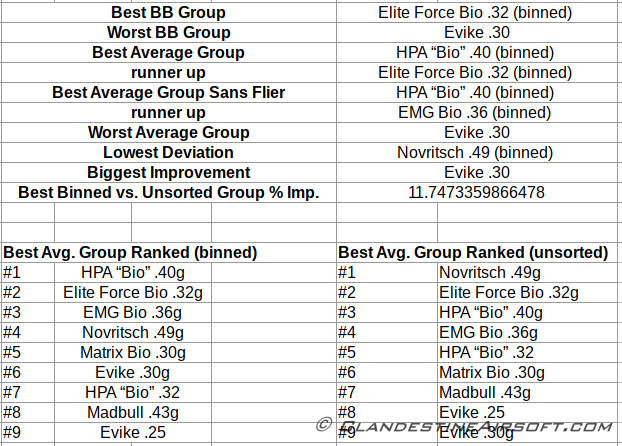

BB Binning ProjectBB Binning Project – written by Hunterseeker5 ABSTRACT BBs are a major limiting factor in the accuracy of airsoft guns, but how limiting precisely and how much improvement can be made precisely is yet to be properly quantified. To this end we sought to construct a machine which would sort, or segregate into bins, BBs based on their mass distribution consistency and then test its efficacy against a variety of popular brands of airsoft BB. The results were substantial improvements across the board, with universal reductions in average group size and broad improvements in regards to grouping standard deviation, maximum group size, minimum group size. In terms of percentages, improvements averaged approximately 10-25% depending on the specific metric. In summary, injection moulded BBs show marked improvements in regards to precision when binned with our method. This, combined with other research undertaken, have yielded startlingly large performance gains with relative ease, inviting further questions regarding the actual mechanical limits of the 6mm smoothbore-backspin system in regards to ultimate accuracy. INTRODUCTION Gosh, I feel like it has been forever since developed or wrote anything for the airsoft industry. I guess that is because it has been. I've been off sunning myself in greener pastures, indulging in other projects, and generally enjoying being rid of the variety of challenges and problems with the airsoft industry. Chief among them are the twin problems of flagrant intellectual property theft and a crushing downward pressure on prices. This has left me with a whole suite of different ideas still collecting dust on the shelf, not worth bothering to put in production, that simply won't ever see the light of day. The Q-hop, a novel type of barrel, a complete bespoke precision rifle system, and so forth. You would rightly then be asking what the heck I'm doing here now? Well one day I had an itch I wanted to scratch, the problems with poor BB quality and piss poor accuracy even among “premium” brands was annoying me in my precision-rifle-games with friends. So, BBs, we all shoot them and none of us get the accuracy we want. I've spent much of my airsoft career chasing fringe accuracy improvements for specifically this reason. About a year ago, I finally got around to empirically testing lapping, on an already very very accurate barrel, and to my astonishment discovered it shrank group sizes by 20-25%. That was WAY greater gain than I had imagined, I expected more like 5-7%, and opened the door to another question: just how much of this shit accuracy is due to BB quality being crap? What if I could bin BBs, that is to say sort them by quality, to tighten groups and kick out those pesky fliers? Technically this isn't new, people have been trying to sort BBs for decades now in pursuit of better accuracy. Placing rounds, one by one, on a crack scale and sorting by mass, measuring with calipers for diameter, and so on. Clearly though, for my efforts, such a process would have to be automated as there is no way I'd do the airsoft equivalent of “handloading.” That said it has the possibility to substantially improve accuracy. There is another problem with this though: it is fairly easy to sort BBs by diameter and weight, in fact a decent factory should have already done this for you with a quality BB. It is possible I could build a machine to do this to even tighter tolerances, but what I wanted to do was test for something much harder: sphericity and density consistency. You see, we all know bubbles are the bane of a BB's existence, and so we regularly break them open in tests to qualitatively assess their consistency. That is only part of the issue though. Plastics don't typically come in sufficient density to make BBs, thus dopants are added to increase the mass. For example when certain ferrous dopants are used, the BBs can become mildly magnetic as some people may have observed. Why do I bring this up? Because the blending of those dopants with the plastic may be imperfect, there may be settling in the injection mould before the plastic hardens, or any of a couple other potential sources of inconsistency, and so the BB may be visibly perfect when split however it may have worse mass distribution than a BB with significant bubbles. How do you test this? How do you even test for voids in the BB without cutting it open? Simple: spin up the BB, nice and fast, and it will be forced to rotate around its center of mass. The worse the BB wobbles, the worse it is. Issues with sphericity can also be readily observed here. So how about a machine that individually spins each BB, measures the difference between geometric center and center of mass, and bins the BBs accordingly? That was the goal. So, one sunny afternoon, I rung up Ben over at Clandestine Airsoft and mentioned this to him. We agreed it'd probably never make any money, but it was an interesting enough question it was worth pursuing just for tits and pickles. Fast forward a month or two, a couple iterations, and a few nights and weekends and..... here we are, a technically functional machine, that sorts BBs into four different bins. Bin #1 is the most stringent and bin #4 the least. But everything is nothing without quantification, and so that is what I will expound on here. It also makes for an opportunity to compare BB brands. After all, this machine only does one flavor of sorting, there are dozens of other mechanisms by which BBs could be binned. The two major problems with going down that multi-machine road though are the number of bins you create and your yield, that is to say how many BBs end up in your final “best” bin. So here we are, quantifying JUST this machine and its effects on a couple different brands of BB. Madbull .43g - These are not exactly what you'd call stellar quality ammo. Their swirls and voids are the stuff of legend. That is why I picked them as the first ammo to bin and see if you could put a shine on a turd, or at least a turd colored Madbull BB. To be entirely fair to Madbull, this bottle is years old, as in maybe 8 or more years old. I don't even remember when I bought it, I just remember getting sufficiently poor performance from it that I shelved it and there it sat until this project came along and I wanted to scratch the itch of “can I sort the crap out of this bottle?” Elite Force Bio .32g – This is what I play with these days, not because it is the best, but because they are cheap, readily available, typically are void-free, and qualitatively seem to be pretty darn decent. In this day and age where you have no time, hate everything, and don't give a fuck, being available for cheap on Amazon Prime with 2 day shipping tends to be a trump card when it comes to consumables. YMMV. Novritsch .49g – If you were to ask someone who doesn't know what they're talking about what the most accurate airsoft BB out there is, dollars to donuts they'll say Novritsch. In terms of sphericity and density consistency they're orders of magnitude off the Bastard Pearls (also sold under a wide variety of other brands), but I've never seen a shred of empirical evidence comparing them other BBs out there. Their density though makes these, arguably, the “premium” Novri BB, and thus one of the most interesting subjects of this test. There aren't too many other BBs out there in this density class. While cognitively I know what 500 BBs looks like, I just had to laugh when I pulled this little bottle out of the box. Its diminutive size is just comical compared to all the other bags and bottles here. That said they the BBs appear to be good quality. I nipped a couple open and found no voids and a very consistent grain structure, however they are VERY brittle and seem almost to fracture in a conchoidal pattern. My understanding is that the OEM on these is BLS, the same as many/most other quality BB brands, so I would expect these to perform about on par with several of the other quality BBs here from the same OEM. High Power Airsoft (HPA) “Bio” .40g – This is another brand here OEMed by BLS. This brand is in the spotlight for false advertising at the moment. Without digging into the details, it looks like their “bio” BBs actually contain styrene, a monomer used in non-biodegradable plastics. And this, amusingly, runs counter to their marketing claim on the bottle which is that they are “US Laboratory Tested & Approved.” (ref. Airsoft Atlanta 2019) I'm not interested in dragging out and parading around the drama llama of who said what when, but I am very curious to see how these actually perform. Of note: they're quite shiny, and the bottle's contents absolutely stink of styrene unlike, say, EMG or Elite Force whose bio BBs have a distinct PLA smell to them. High Power Airsoft (HPA) “Bio” .32g – same game as above, but lower density. Interestingly these have a bit of a whiff of PLA to them, so it is possible they use different polymer blends, not just dopants, in different BB masses. Of note is the fact that PLA is substantially denser than ABS (the S in ABS is Styrene), which is why you often see bio BBs available in slightly higher densities than their non-bio counterparts. There are, of course, a few exceptions to this for other reasons but I digress. Evike “professional grade” .30g – I've never shot these before. They look like medium shiny white BBs. I want to put in a disclaimer here: these BBs are absolute dogshit, and I would argue unsafe for use in AEGs or any other system that can eat itself in the event of a BB jam. Why? Well I shot my first group, and when I got to the paper I thought I'd somehow forgotten to shoot several shots. They were just missing off the paper. So I shot another 5 groups, this time with targets closer to the center. Once again, BB's were magically missing, but this time I'd watched their flight carefully and saw the most astonishing flier occasionally rear its ugly head. I then binned a selection of these BBs and was appalled to find some BBs were so far out of round they actually clogged up the machine at multiple points. As far as their general quality, usually a substantial number of BBs end up in the top two bins. Generally the worst bin, the “discard” bin, is practically empty. Maybe a few unluckly bounce-outs end up in it. Not with these BBs. The worst bin was as full as any of them. Meanwhile the top bin had precious few BBs in it. I realize I was saving the results for the “results” section, but these were so stand-out bad I wanted to make a note of it, even though I haven't totted up the numbers yet. EMG International Bio .36g – This is a popular Evike house brand of premium BB. (EMG stands for Evike Manufacturing Group) They appear to be slightly less shiny than some of the other brands here, although that isn't necessarily a bad thing as some sheen can come from wax/mould release left on the BBs; I'd rather clean, accurate, and duller finish BBs than shiny shitballs that rapidly foul my hop and barrel. Evike “professional grade” .25g – Same as above. Never shot them before, medium shiny white BBs. Interestingly these are the only BBs in this test to come in a bag rather than a bottle, and the bag seems like it is trying to be air tight but has a hole in it somewhere so isn't. I don't know if that is supposed to be a feature or a bug but there it is. They also claim less than 5% internal bubbles. Not sure if that is meant to mean less than 5% of them have bubbles, or if each one is less than 5% bubble. Because I have a sense of humor, I cut 5 of them in half and found a single bubble, of varying size, vaguely in the center of each. These BBs also gummed up the works when it came to binning, but at least all of them managed to make it onto the target. I would also strongly recommend avoiding these. If they'll clog my binning machine, I dread to think what they'd do to a timing and jam sensitive AEG. Matrix Tactical Systems (Evike) Bio .30g – I'm beginning to wonder what I used to do with my life before I started sniffing BBs. I've never shot any of these before either, however they don't smell like PLA (one of only a handful of “bio” plastics, and the obvious choice for bio BBs), they don't really smell strongly of styrene either. They do come in an old-school nozzle-fed bottle though. Given my experiences with the previous two Evike branded BBs, I was gritting my teeth testing these BBs. I was pleasantly surprised though when every single BB was able to hit the target and none of them jammed the binning machine. So that is nice. JSB 18.13 grain – This isn't a BB, it is a pellet for use in air rifles. Consequently it wasn't shot out of an airsoft gun, it was shot out of an FX Crown. I intentionally shot these five groups rather casually, more casually than I shot the above airsoft groups, and of unsorted ammunition straight out of the tin and into the magazine. (these magazines substantially reduce accuracy, as do unsorted pellets) Why? Why include this at all? I wanted a concrete comparison between what me, with a rifle, at my “worst” will do as a comparison to what I'm doing with an airsoft gun under reasonably good conditions. One can safely assume then that shooter error, my error, would add no more than what is seen with this rifle. I averaged .71MOA, which is crap for what this rifle is capable of. Sorted pellets, shooting off of bags instead of a bipod, single loading, and actually taking my time would shrink that substantially. .71MOA though is infinitesimal compared to the size of these airsoft groups, smaller than the margin of error in fact. Thus I think I make a compelling argument for shooter error, unless otherwise noted, having a negligible effect on group size. METHODS A word on testing protocols. The basic protocol is very simple: first shoot a couple BBs through the barrel to seat the nub and warm up the hop/contaminate it with whatever mould release is left on the BBs. Then shoot 5 groups of 5 round rounds each of virgin BBs. Next a “handful” of BBs are binned, typically BBs are simply added to the binning setup until a minimum of 35 bin 1 (the best bin) BBs are acquired. Then repeat the above with the binned BBs. Each group is shot rested at 15 yards indoors in dead still air. It is entirely possible, if not likely, that longer ranges would result in a greater advantage to the binned BBs, as the primary advantage with good quality BBs would be more consistent aero effects as most BBs are pretty darn round, however 15 yards is the longest convenient indoor range with absolutely dead air thus 15 yards it is. The rifle is my personal modified VSR10 with an enhanced cut R-hop, 100,000 pass lapped barrel, and a variety of other modifications. It puts out about 2 joules. The extreme spread of each group is measured, and then that is averaged to create an average for a given BB test. In total, 100 individual groups were shot and measured, granted one was shot with a rifle. We'll come back to that last part. Now for a quirk: a second average is created for each binned test with ONE flier out of the 25 shots excluded. Why? Well no good reason actually. When I tested the lapped barrel, I pulled a shot and knew it before the impact, so when it came time to tot up numbers I did averages both with and without that flier included. With that flier the average improvement from lapping was 20%, without it was 25%. When I started testing different BBs, the first brand I tested was Madbull .43s. There was also a SUBSTANTIAL flier in one of the binned groups. So I once again did averages with and without the flier. When it came time to do the next BB test, there was no egregious flier, however for the sake of consistency I once again identified the worst shot and did averages with and without it. This takes me conveniently to my next point: the correct way to do this analysis isn't with group size, it is mean deviation from mean center. There is a lot of time and math in totting that up though, so for now group size will have to suffice. And one further addendum on fliers, somewhat shoehorned in here as I hadn't anticipated anyone would be so bad as to miss the target entirely, but thanks to Evike managing to exceed even my expectations, I now have to write an explanation for calculating group size with a miss. In short, what you do is calculate the smallest possible group size which could allow for a miss. So you measure to the nearest edge of the target from the furthest impact in the group. In essence you give that miss the “benefit of the doubt” and calculate it as if it was as near a miss as physically possible. RESULTS/DISCUSSION (see fig. 1 and 2) The average reduction in group size from BB binning across all BB brands tested was 15%, and every single test showed some improvement in performance. Keep in mind that a 100% reduction in group size is the maximum possible, and would result in a group size of 0mm. That is quite significant. If one flier out of the 25 rounds shot for the binned groups is discarded, the average improvement increases to 24%. The top four best averages were all binned BBs, and the best group shot out of all 95 groups shot was with binned Elite Force Bio .32g BBs The greatest improvement was a whopping 45% reduction in group size from the Evike .30g BBs. Those BBs though, as noted above, were incredibly poor quality so had substantial room for improvement. I expect that they were not subjected to diameter controls and similar, something this binning process assumes was already done, and so additional sorting steps could have had an even more substantial effect. The number of BBs ending up in bin 1 with both “regular” Evike brands (the .25s and .30s in non-bio) were unusually small necessitating many more BBs to be binned in order to achieve the required number to test. Additionally, an unusually large number ended up in bin 4, the “discard” bin. Thus while binning can improve these two BBs, really I'd just suggest avoiding purchasing them. Standard deviation is a measure of how consistent results are. One would expect binned BBs, not just to form smaller groups, but to be more consistent in terms of group size. I quantified this by generating a percentage improvement over unsorted BB standard deviation versus binned BB standard deviation, within type of course. The average improvement (reduction) in standard deviation was 20%. All but two brands saw an improvement here, and those two were the much maligned Evike .30g and the Madbull .43g, the latter due in part to the single aforementioned egregious flier. If said flier were omitted, the Madbull STDEV improvement from unsorted to binned would go from -15% to +29%. How about the minimum and maximum group size improvements? Did binning shrink only the biggest groups, leaving the best groups from the unbinned BBs uncontested? Or did it improve groups across the board? As it turns out the latter. Every single smallest group size, that is best out of each round of 5, was improved by binning. The average improvement was 12%. Interestingly, the Novritsch .49g BBs and HPA “bio” .32s actually saw the greatest improvement, with the smallest group shrinking by a whopping 18% and 20% respectively. So not only can premium BBs benefit, they are able to benefit substantially. In reduction of largest group size, every brand saw gains except, again, the maligned Evikes, this time the .25g BBs. There is no good excuse for this one, as on this target there were what normally you'd call four fliers, the problem is two fliers clustered touching each other high left, and two more clustered touching each other low right. Eliminate any one and the group size remains essentially unchanged. And how about how all the BBs ranked? As noted before, the top 4 best tests were all binned BBs. Unsurprisingly, there were really only four brands of “good” performing BBs here, and they were, in order of rank (binned): HPA “Bio” .40g, Elite Force Bio .32g, EMG Bio .36g, Novritsch .49g. Take away the binning and that order changes to Novri, EF, HPA, and EMG, but the pattern is clear. The Novri's had an absolutely enormous advantage in this test, having a substantially higher density than any of the other BBs here. This makes them less subject to all manner of environmental insult, including from muzzle turbulence. Conversely, the one brand of .25s I'd have considered at significant disadvantage as they were being pushed too fast, however their innate lack of quality I think was a larger stumbling block. Somewhat unsurprisingly, the “antique” madbull .43s were poor performers both before and after binning, although they never jammed or otherwise caused problems. I hypothesize that one of the factors here may have been, not mass distribution consistency, but mass and diameter itself. A group of BBs which posess both perfect sphericity and mass distribution will still perform very poorly if mass and/or diameter vary considerably. And now for a series of interesting statistics: The best BB group was Elite Force Bio .32s (binned) with a group size of 16.36mm. If you take a moment to do the math, that is 4.29MOA. A milspec M16 (AR15) is expected to shoot about 4MOA with issue ammunition, so for one brief hopeful whisper of a second, at extremely close range, an airsoft gun managed the accuracy of a military rifle. Pretty cool eh? Of course said AR is expected to do that reliably and at 100 yards, but potato potato. The worst BB grouping record was held by Evike's “professional grade” .30g BBs. This was a group shot at the middle target on an 8.5x11 standard printer paper size sheet, and somehow this BB brand managed to squeeze out a flier so bad it completely missed the entire paper. And so there it is, a whopper of a 121.5mm “group.” Any of the other numerous misses completely off the page with the, not one but TWO, sheets of unbinned BBs I shot to give this ammunition the benefit of the doubt could have technically been this large, but as they were unrecorded they must be given the benefit of the doubt. Never the less I am happy to Crown Evike “professional grade” .30g BBs the absolute worst ammunition tested here and by a substantial margin. The best average group size was held by HPA with binned “bio” .40g BBs, the runner up being Elite Force with, obviously binned, Bio .32s. The best average group size sans flier was again taken by HPA with binned “bio” .40g BBs, the runner up being Evike Manufacturing Group (EMG) .36s, also binned of course. The lowest deviation, that is to say not the smallest but most consistent sized groups, was taken by Novritsch .49g BBs (binned), and that binning was a significant factor as it reduced Novri's standard deviation by 26%. CONCLUSION In summary, there were consistent improvements across all relevant metrics in regards to binned vs. non-binned BBs. These improvements are substantial in nature, and represent improvements consistent with other significant accuracy enhancing technologies such as advanced hop ups, extensive lapping/bore re-working, etc. Some BB brands however displayed a rather startling lack of initial quality control, quality control issues we had not anticipated to be a problem. Things like BBs dramatically out of dimension ought have been excluded at the factory, in our opinion, however additional binning steps could be created to exclude them. Given their prevalence however in the samples tested, namely from Evike's “professional grade” brands, this type of binning is likely not cost effective when it comes to the discard ratio as compared to simply starting with higher quality BBs. Never the less, further segregation by BB mass alone may yield yet more binning steps which could be undertaken to, not discard unacceptable BBs, but simply create additional categories of BB for even greater shot to shot consistency. The actual mechanical limits of the 6mm smoothbore-backspin system are not yet known, and so far all research has yielded startlingly large gains suggesting that there is a real possibility of additional readily accessible performance potential locked within the system.

|