Barrel Lapping Performance

Quantification of the Performance Gain from Lapping This research was originally posted here: https://www.youtube.com/watch?v=rzhYR6s2kJE

Abstract At the request of Clandestine Airsoft, I'm doing a quick writeup regarding a project to quantify the performance gain of lapping. An already high-performance stainless steel barrel with R-hop was selected at random, tested, lapped using a proprietary 100,000 pass protocol, and tested again. The results were an astonishing ~20% reduction in group size. There were also indications that lapping reduced the rate of barrel fouling, though further research into this subject would be necessary.

Introduction Lapping is the machine-tool process of using a softer solid surface to cut a harder one via the embedding of abrasive particles. This process is frequently used to cut gemstones, however has other notable applications as it has the capability to be EXTREMELY precise, and leave very fine surface finishes. Lapping is often used in firearm barrels to remove the tooling marks from fabrication, be that CHF, button rifled, or cut rifled. The latter is considered to be one of the highest accuracy methods of barrel manufacture, yet even these barrels are typically lapped to further increase performance. Airsoft barrels are made via some of these technologies, although unsurprisingly the standard of quality is typically much lower while arguably the need for precision is actually much higher; a rifled firearm barrel will have as many areas of contact with the projectile as it possesses lands, and these run down the length of the projectile, allowing for minor deviations to be evened out without major disruption. An airsoft BB however maintains a hypothetical single point of contact with the barrel's ceiling, held there by an as-of-yet-uncertain but assumed aerodynamic phenomenon. It picks up spin from this surface, and ultimately its accuracy will depend on both the consistency of this spin, in both velocity and axis, as well as its final vector. The result is tiny deviations, inconsistencies in surface finish or straightness, can cause significant deviations in flight. Small wonder airsoft guns typically do not approach the accuracy of firearms. This also highlights a key difference, both in mechanics and technology, between buffing/rotary polishing and lapping. Rotary polishing of an airsoft barrel can indeed produce substantial improvements in accuracy, and it does this by improving the consistency of the surface finish of the barrel. This may however come at the detriment of bore straightness/diameter consistency, merely hovering in one spot too long can enlarge the bore in that area while passing over another too quickly will leave it smaller than other areas more polished. Additionally, rotary polishing does nothing to improve the existing diameter consistency of the bore, again airsoft barrel manufacture typically being of less than ideal quality. Finally rotary polishing leaves micro-scratches, like all cutting methods, however it leaves them neither perpendicular to nor parallel with the bore path, but rather spiraled up and down the bore depending on tool RPM and rate of insertion/removal. This is not an ideal condition. Lapping differs significantly from rotary polishing in that the tool used is rigid, and the tool path is strictly longitudinal. This gives the same benefit of improved surface finish, and improved surface finish consistency, of rotary polishing however it produces two additional advantages. First, it aligns the micro-scratches left by cutting with the bore axis so they are not able to impart off-axis spin to the projectile. Second, it increases bore diameter consistency or “flatness” if you will. This in turn increases the consistency of the point of contact between the BB and the bore, which in turn leaves the BB with a more consistent exit vector. Taken as a whole, and put in simple terms, it makes both your pre-hop and post-hop accuracy better.

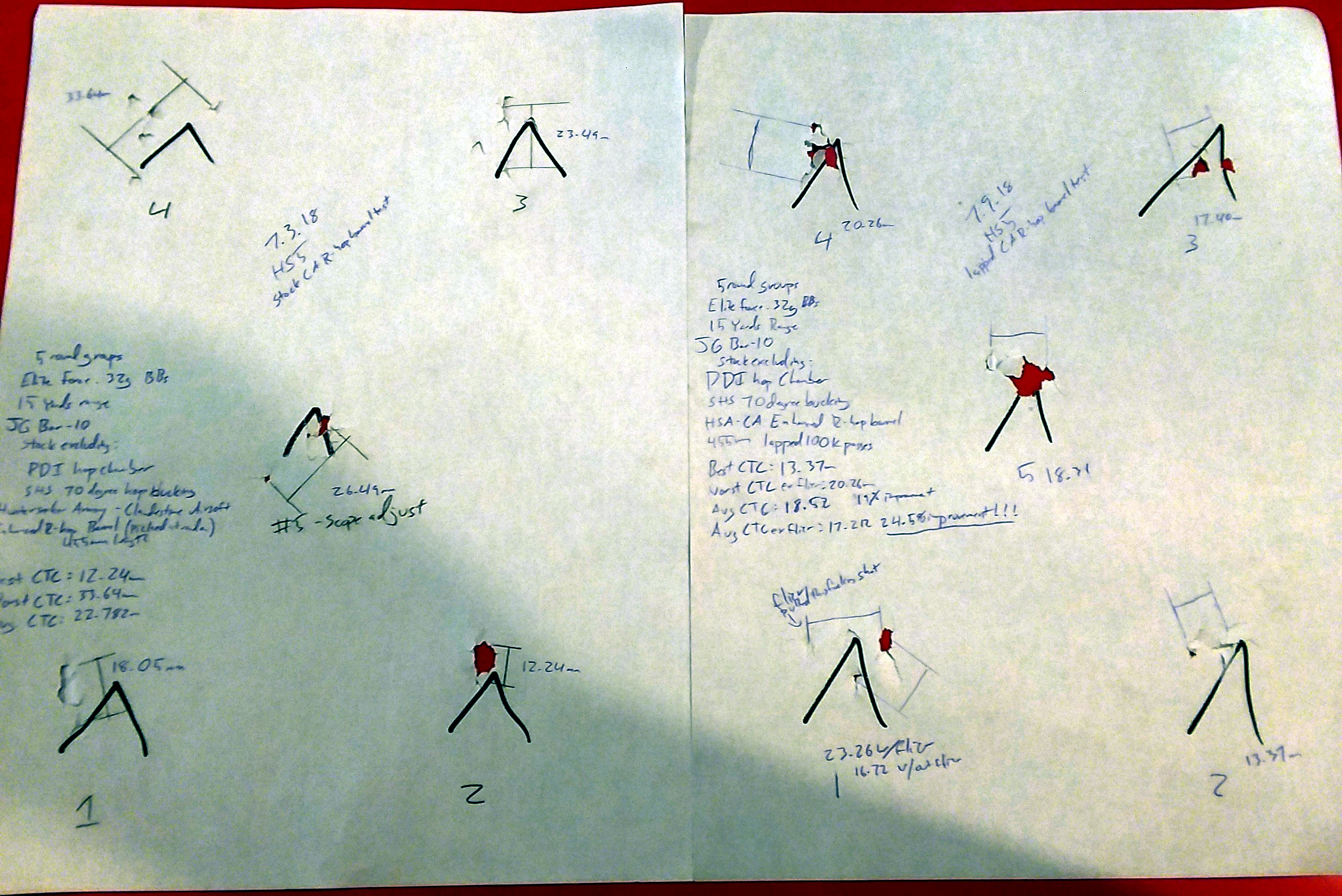

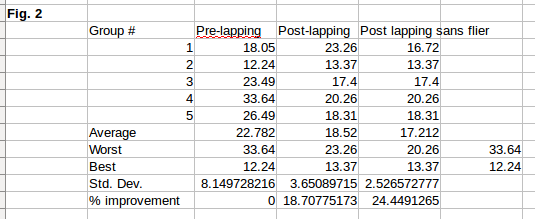

Methods Ideally a sample of barrels from various manufacturers would all be lapped. In this study though only one barrel was lapped. It was a randomly selected Clandestine Airsoft Enhanced R-hop Barrel. There are several common issues raised when lapping tests are performed, most notably that the barrel in question was not sufficiently high quality to start with. The assumption made by this argument is that lapping can only improve a very poor quality barrel significantly. This therefore endeavours to test whether one of the highest performing barrels on the market can be further improved by lapping. The test rifle is a lightly modified JG BAR-10 (VSR10 clone), stock aside from being cleaned, re-lubricated, using a PDI hop chamber, SHS 70 degree bucking, and of course the Clandestine Airsoft Enhanced R-hop Barrel. The rifle was rested on sandbags, front and rear, and aimed using a Leapers AO scope to remove parallax error. The test ammo in question was unsorted Elite Force .32g BBs. The barrel in question was randomly selected out of a large batch. It was then checked for burrs. It should be noted that deburring is part of the HSA R-hop installation process, however it is critical to check all barrels before lapping because while a minor burr can go unobserved in a barrel's performance, a burr's potential to cut/damage the lap means it can assert itself when lapping and invalidate the test/reduce performance. The barrel was then cleaned with a standard protocol of swabbing first with a light silicone oil until patches come out clean, and then swabbed dry. Several hundred rounds were fired through it to break in and bed the hop, and it was once again cleaned with the standard protocol. Thirty (30) rounds were then fired through the barrel with the test ammo to reset the barrel and re-bed the hop. Five groups of five rounds each, twenty five shots total, were then fired indoors at a range of 15 yards in absolutely calm air. The barrel was then lapped with the 100,000 pass protocol. The exact procedure is, unfortunately, a trade secret however one might look at the HSA Level 4 lapping kit and surmise...... No additional work was performed on the barrel, no bore scraping, no crown enhancing, just lapping. The barrel was then thoroughly cleaned, again using the standard protocol, and thirty rounds with the test ammo were fired to reset the barrel and re-bed the hop. Another five groups of five rounds each, twenty five shots in total, were then fired, again at 15 yards under identical conditions. Each group had its center-to-center (CTC) size measured and recorded. One shot was pulled when shooting group 1 on the post-lapping test. This flier was noted for later analysis. Results/Discussion Figure 1 contains an image of the raw data, while figure 2 lists the results and mathematical analysis. Pre-lapping, the average group size was 22.8mm, while the post-lapping average group size was 18.5mm. This is a substantial improvement of 18.7%. And, remember, an improvement of 100% would be a group size of 0mm. Removal of the pulled shot reduces the post-lapping average group size to 17.2mm, and increases the improvement to 24.4%. That is huge, far larger than expected. Again, keep in mind that this was already a very high performing barrel. Some of the best airsoft shooters in the world compete in Japan's 30m challenge, where a 100mm spread at 30m is considered exceptional performance. Extrapolating that angular MOA backward to 15yards, you get a group size 45.73mm. While there are obviously limitations to this sort of analysis, as range does not scale linearly, they shoot 10 round groups not 5, and they're allowed to bin ammunition, clearly the performance of this barrel pre-lapping was substantial. The best and worst groups shot were from the pre-lapping set, at 12.24mm and 33.64mm respectively. Only the two best groups from the pre-lapping set were better than the worst single group (including flier) from the post-lapping set. The standard deviation of the post-lapping set was also less than half that of the pre-lapping set. There is another interesting trend I noticed here, which is that on the pre-lapped test, group sizes seemed to increase. The sample size here is quite small, to be clear, however this may also be evidence for lapping inhibiting barrel fouling. It is well known that BBs, particularly PLA bio BBs, cause a buildup of plastic in barrels which needs to be cleaned out. What we're seeing may be evidence of that happening as the groups progress. To further explore this, group number was graphed against group size, and trend lines were applied. (fig. 3) It is important to note that this phenomenon should not be linear, however for analysis of such a small sample it seemed expedient. The slope of of the trend-line post-lapping is nearly 1, that is to say almost level, little increase in group size over time. If including the flier, it is actually negative. The R^2 of .4 doesn't indicate an extreme correlation, but a correlation none the less. The pre-lapping trendline however possesses a slope of 3.8, with a better R^2 of .55. Conclusions The barrel lapping protocol used here made an astonishing performance improvement in an already exceptionally high performing barrel. These gains are several times what the author expected, thinking the improvement would be in more of the realm of 4%. The progressive increase in group size across both samples also hints at, but definitely does not conclusively show, barrel fouling as a process. This is very interesting, and a potential avenue for further research. How much does lapping slow the barrel fouling process? How rapid is that process anyway? Does it ever plateau, or can an increase in group sizes be noted essentially until plastic occlusion makes the barrel un-shootable? Further research into this would be required.

|